An Unusual Way to Get the Lowest Cost for Your Refractory Project

We’ve all heard the term “penny-wise, pound foolish.” This is particularly true when it comes to refractories — sometimes the lowest cost solution means spending more upfront in order to save significant maintenance costs in the near future.

It’s common knowledge that margins in U.S.-based manufacturing continue to get squeezed, so it’s critical for our clients to keep construction and maintenance costs as low as possible. F.S. Sperry supports this goal, since if costs got too high and all our clients moved offshore, we wouldn’t be able to stay in business!

Since we’re passionate about our business (we’ve been serving the Mid-South since 1946), we always examine a wide range of solutions before making recommendations to a client.

A recent example occurred when we were bidding on an industrial furnace project. The customer’s product dragged across the furnace hearth. This created a high-wear area that required significant maintenance. Due to the location and geometry, it was very difficult for them to get a good bake-out of the refractory material and therefore maximize its engineered properties.

The customer asked for the “best material” and the “lowest cost” solution. Because of our product knowledge and experience, we reviewed numerous options and projected the entire cost from installation to maintenance for each option. Many end users don’t always consider the maintenance cost when evaluating total cost.

The clear solution ended up having us provide and install engineered shapes. With the engineered shape, we could absolutely control the bake-out process to achieve maximum physical properties, thus limiting future maintenance requirements.

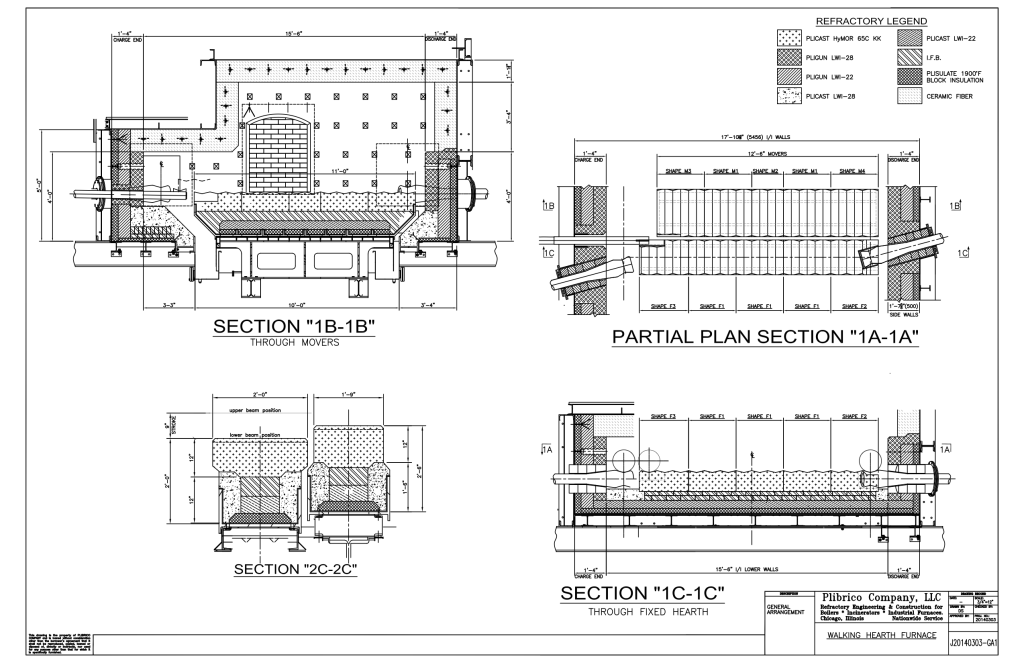

Here are some of the engineered drawings we produced while working with the customer to present the optimal solution:

The key to achieving the customer’s goals was their willingness to consider all the alternatives. We presented them with options that cost up to 20% less up front, but also showed them how the downtime, maintenance and repair costs to patch and fix the wear areas added up each year. Bringing the furnace off-line once before their schedule negated any savings when compared with “low bid.”

Because they were willing to work with us to review different options, they were able to clearly understand the best choice. In the end, we delivered exactly what the customer wanted: the best material and the lowest overall cost.

If we were forced to complete a request for proposal and submit a bid without working with the customer directly, they may have chosen an inferior solution.

Sometimes, the true “low-cost” bid is not the lowest cost solution.

Comments are closed.