Case Study: Foamfrax Veneer vs. Coating

We’re always on the lookout for innovations that improve the performance of refractories and linings.

Though it requires a substantial undertaking to evaluate the quality and performance of new products in our industry, we’ve found that the rewards far outweigh the costs. Of course, we’d never use a product that’s untested, but when we find a new product that delivers significant benefits over “the status quo,” we’re not afraid to use it on the job. Call us pioneers, if you will.

This is a bit unusual in our industry, as some refractory contractors operate year after year using the same products and application methods, irrespective of whether more effective options exist (from either a total cost or performance perspective).

This is a case study for one of the first installations of the Foamfrax insulation product, which we performed back in 2001.

Customer Challenge

In 2001, a steel manufacturer in the Midwest needed to repair its continuous roller hearth furnace. After six years of service, the ceramic fiber module lining in this unit had become severely fluxed and as a result, the lining system had sustained some mass loss. This fluxing phenomena and shrinkage gaps in the lining caused the furnace shell temperatures on this unit to gradually increase.

The repair options to lower the furnace shell temperature were as follows:

- Completely replace the lining

- Add more insulation on the existing lining hotface

One of the main factors in the decision-making process was speed. Could we complete the repairs during their monthly one-day plant shut down for maintenance? Or would they have to incur costly additional downtime?

We chose to add more insulation to the existing lining hotface, and knowing our customer’s need for speed, we chose to use the Foamfrax Insulation System.

Foamfrax is a unique, proprietary form of ceramic fiber made by Unifrax. We selected it because it can be quickly installed, and the plant had a one-day maintenance shut down every month.

We decided against using a standard coating because our experience has been they do not work for these applications. We don’t doubt the engineering and science behind them, but in the field we’ve seen little measurable success relative to their cost.

Installation

Prior to the Foamfrax installation, we wet the lining with water to minimize airborne fiber generation and remove loose material from the hotface surface. (Note: if you need to remove any after-service refractory material, refer to the product MSDS for proper material handling guidelines.)

We kept in place any of the glassy surface material that still maintained its physical integrity. After this procedure, we wet the lining with water once again, and then gunned a 3” (76mm) veneer of Foamfrax Grade II fiber onto the module surface.

The completed Foamfrax lining added insulation thickness to the existing lining and filled any shrinkage voids on the surface of the modules. Our team took extreme care during installation to work around the burner areas and the removable roll bungs.

Results

Once in service, a noticeable and ongoing reduction in furnace coldface temperature was observed. Based on our experience with this project and numerous jobs since that time, we have found that Foamfrax performs better than coatings as a veneer to existing module linings to upgrade and protect the refractory.

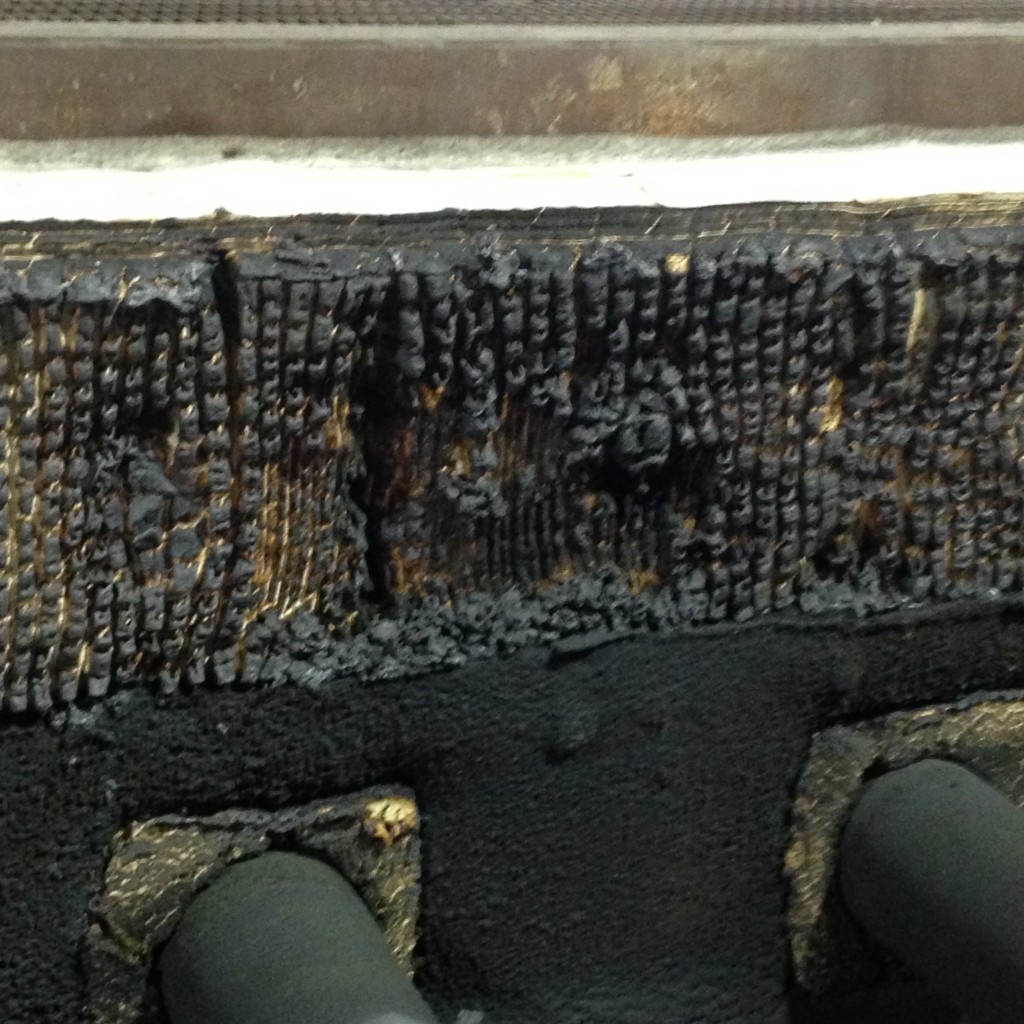

These two photos were recently taken after 8 months in service in the same furnace. This photo is our Foamfrax installation.

This is a photo of the coating that was installed by a different vendor.

The Foamfrax veneer clearly out-performed the coating.

Benefits

The installation of Foamfrax Grade II Insulation provided the following benefits to the manufacturer:

- Turnkey Installation

A specially trained Unifrax distributor/contractor was able to supply materials, equipment, and installation as a complete package. - Fuel Efficiency

The additional thickness of Foamfrax Insulation sealed all lining openings and added insulating value, resulting in reduced furnace shell temperatures and reduced fuel usage. - Extended Service Life

The Foamfrax Insulation upgrade provided extended service life for the furnace lining and the customer avoided a complete lining reline and costly downtime. - Installation Speed

Due to the quick installation of Foamfrax Insulation, furnace sections were easily completed during the monthly 24-hour maintenance shutdown of this furnace.

If you need to reduce the shell temperatures of your heat processing equipment or just want to upgrade a deteriorated lining, consider Foamfrax, and tell us about your project.

F.S. Sperry is the largest installer of Foamfrax in the United States.

Comments are closed.