Refractory Technical Datasheets Don’t Tell the Whole Story

Refractory technical datasheets are important. They provide relevant data that should be considered in the overall process of selecting a particular refractory for a specific application.

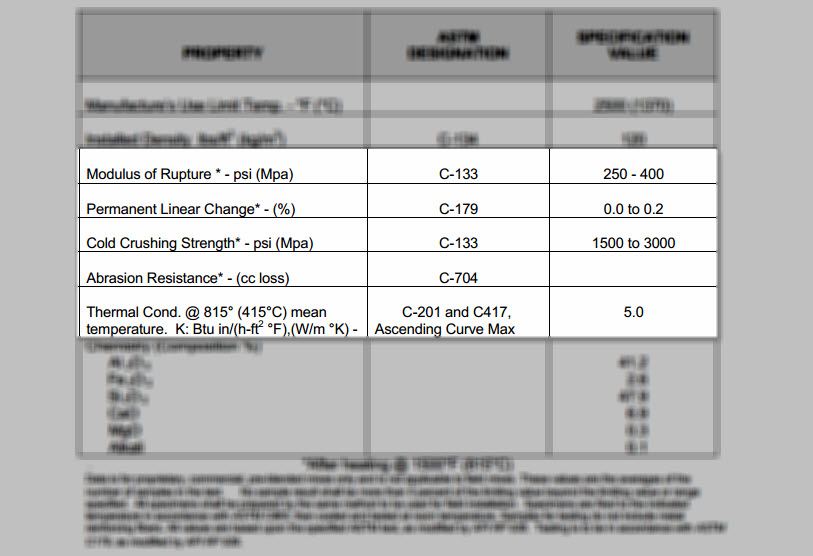

Technical datasheets list the refractory’s physical properties and the pertinent testing results, as well as the chemical makeup of the material. While they are important, technical datasheets should never be considered as a stand-alone reason for selecting a refractory.

The Difference Between Projected Performance and Performance in Service

While many refractory products may appear on paper to apply to a specific installation application, the results in service may vary dramatically. One problem with relying solely on datasheets is that datasheets don’t take into account all of the other factors affecting the material’s performance. This includes environmental and structural/mechanical factors, the specific fuels used etc., all of which will contribute to the refractory performing as intended.

This is especially true in molten metal applications, where liquid metal is in contact with the refractory surface. While some refractories may appear to apply on paper, the actual results may be very different — even disastrous.

One of the biggest misconceptions is the temperature limits of a refractory. Just because the technical datasheet might show a refractory in-service temperature up to and exceeding 3,000 degrees F, it does not mean that the refractory will necessarily function at those temperatures under load.

Other factors may also affect the eutectic of that refractory, whereby material that seemingly should function at 3,000 degrees F could actually fail at much lower temperatures.

Technical Datasheets Are Simply a Data Point

The competent refractory contractor knows how to incorporate technical datasheets into the overall scope of the project and use them to help select the material that is best for the application.

It’s not a good practice simply to select a refractory based on its datasheet. They’re a data point, but not the entire story.

Make sure to consult with your refractory installer before making the final selection. In our next post we’ll share a technical datasheet and share how we evaluate them during the refractory selection process.

Comments are closed.